A global shift away from fossil fuels is leading to a boom in lithium-ion battery applications, ranging from electric vehicles to energy storage systems. The market is projected to have a value of €250 billion in Europe by 2025. To secure local value creation and jobs, there is now a concerted push to achieve European sovereignty in LIBs, including the European Battery Alliance to promote manufacturing, and research and innovation initiatives like “Horizon 2020” and “Battery 2030+”. The institutions involved have announced multi-million euro grants to foster LIB ventures, secure resources, and build mega-factories.

However, European firms face a challenging industry environment, with significant barriers. The landscape for lithium-ion battery manufacturing is dominated by Asian players, which account for 89 percent of global manufacturing capacity. In contrast, European firms hold a paltry 3 percent share. The Asian giants are entering Europe to meet local demand. In addition to competing against their scale and cost advantages, new entrants must reckon with a fast-paced and dynamic landscape. The question is: Do European firms still have a chance to participate in a local LIB value chain, or is it already too late?

WHY EUROPEAN PLAYERS SHOULD ACT

The rapid evolution of LIB technology and industry also offers opportunities. There are four strategic reasons why a second chance for European LIB players and equipment manufacturers is beginning to emerge.

Firstly, European manufacturers not only have access to funding, but also can benefit from favorable economics. In comparison to Asian imports, local production offers about ten percent cost savings from shorter logistics to end customers. Moreover, recent investments in developing local raw material resources like lithium and nickel help cut costs.

Combining these factors with elements such as the factory-of-the-future and digitalization can provide an additional ten percent in savings. Secondly, the growing pace of automotive electrification represents a source of unmet LIB capacity demand. For example, electric-vehicle adoption rate forecasts are being revised upwards, with more than 300 models expected to be launched by 2025. Automakers have been scrambling to secure LIBs. This offers an opportunity for firms that can meet quality, performance, and sustainability requirements. It should be noted that it can take up to five years from a greenfield LIB plant to full operational capacity. It is critical for firms to align their production ramp-up with electric vehicle (EV) sales in this period.

An evolving application space offers a third reason. LIB technologies are not monolithic. Cost considerations and product requirements dictate their suitability for each application. For example, nickel-cobalt-manganese and lithium-iron phosphate cathode chemistries are respectively preferred in electric cars and buses. The same applies to future applications such as robotics, aerospace, medical devices, and industrial applications, representing a blue ocean for firms to provide tailored offerings. Engineering a shift away from standardized mass-produced LIBs to customized batteries offers Europe’s firms an opportunity to stand out from the crowd – a strategy that has proven successful by European players in other industries.

Concurrently, coexistence of LIB technologies in the foreseeable future ensures that investments will continue to generate returns – even in case of future fuel-cell-powered transportation solutions.

Finally, entering the space allows firms to prepare for the future LIB landscape. New entrants will naturally start as laggards, trailing the incumbents’ resources access, scale, and competence in today’s LIB technology. However, advanced LIBs are already under development to address the limitations of this generation. For example, solid-state batteries are expected to be commercialized in four to five years, with technologies like metal-air on the horizon. These require significant tacit knowledge in battery design, chemical and thermal properties, interaction processes, cell manufacturing, automation, and assembly. If Europe is to become a player in commercializing the technologies of the future, the experience gained in catching up to today’s LIB leaders is essential.

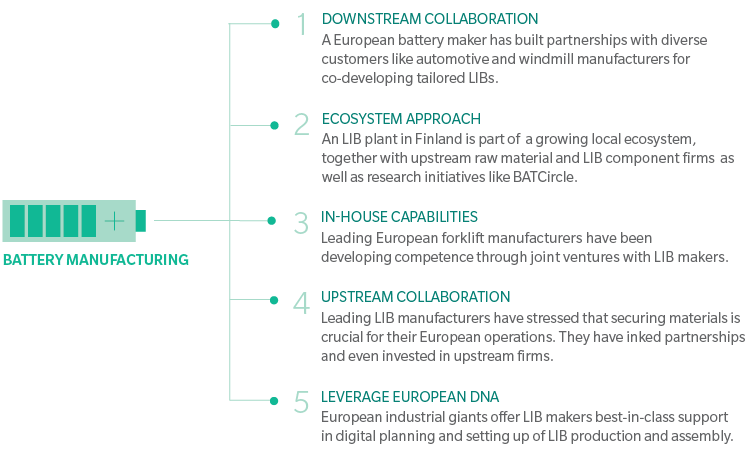

Exhibit 1: Strategic levers in battery manufacturing

Source: Oliver Wyman analysis

Setting up a greenfield battery plant can take up to 5 years

LEVERS TO ACT

The industry dynamics and technology development offer European firms the chance to secure future value creation. But in their pursuit, they must keep five important strategic levers in mind. (See Exhibit 1.)

Firstly, they must identify end applications and collaborate with customers to derive performance specifications and lower costs. Being customer oriented will help to develop and commercialize the LIB technology best suited to those requirements. It also ensures a dynamic view on demand, minimizing the risk of overinvestments and oversupply.

Secondly, they must proactively build ecosystems spanning the complex value chains. This allows firms to tailor R&D efforts and stay abreast of technology developments and breakthroughs. Orchestrating the ecosystem will enable them to commercialize the LIB solution quickly.

Thirdly, they must build their own in-house capabilities in LIB technologies. Successful LIB solutions not only require developing new active materials, but also need innovations in passive materials, solutions for battery and thermal management, process design, and equipment. To this end, they must invest in talent and equipment to build competence in design, development, and production.

The fourth lever is upstream partnerships to manage investments and costs. Firms must build strong relationships to ensure access to resources necessary for scaling production and controlling material costs. For this, they will need to cooperate with miners and processors to mitigate supply-chain risk.

Finally, they must leverage their European roots. Industrial firms in Europe have historically established and built brand value and industry relationships. They also have a track record of meeting tough sustainability standards, which is especially important given the environmental concerns that are driving vehicle electrification. Crucially, they have exposure to innovative production technologies and manufacturing process efficiencies, which offer a cost-savings potential second only to material optimization. European firms would strongly benefit by exploiting these advantages.

TIME TO ACT

The advantages of a localized LIB ecosystem are clear. Given the growing demand in Europe – and more electrification applications on the horizon – the absence of a local LIB industry will mean significant value migration and painful structural changes. While playing catch-up with the current industry leaders will be difficult, waiting will only widen the gap and make it that much harder for European firms. As demonstrated by Chinese LIB makers who capitalized on tailwinds to catch up with Japanese and Korean players, European firms with the right strategy have a chance to be become industry leaders in the future LIB landscape.